GRIGIO – patent pending tensioner units

GRIGIO is a ROBUST product which means reliable, SIMPLE for it’s of easy use, VERSATILE for it has more application possibilities, ANOX for it resists oxidation, POLYHEDRIC for it can be transformed in different applications, ELEGANT, a quality that can not be described, a look is more than enough; the main reason that makes it this interesting is that it’s CHEAP; this characteristic from our point of view is especially important for it will allow it to impose itself in more markets, even in those emergent markets that are in need for valid products but with a moderate starting price.

The different kits for chains are sliding blocks made of POMH (type GV), crowns mountend on bearings (type GPNB and type GPKB); for the tensioning of belts polyammide rollers (type GPRP) or galvanized steel rollers (type GPRU). All of the functioning values are indicated in our technical charts.

Installation

In order to make GRIGIO working in the best way on the chain or belt transmission, it is necessary that it is placed correctly. The tensioner must be mounted on the driven section of the transmission and the nearest possible to the driving motor.

Here are some easy assembly steps to be followed in phase of installation:

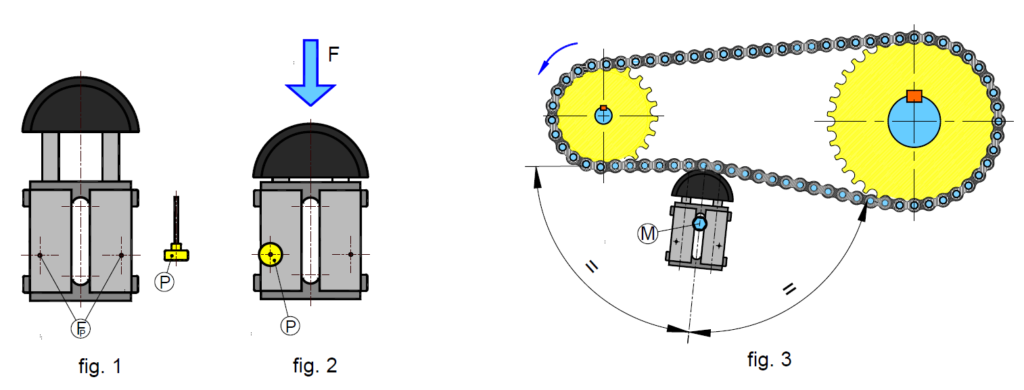

1) Press the columns, so that when the springs are compressed, they can enter completely inside the tensioner;

2) Fit the P preloading pin in one of the FP holes on the bodies (fig. 2);

3) Place GRIGIO tensioner preloaded, into the transmission and push it toward the chain or the belt. Tighten the M screw (if it is necessary use two screws). In this phase pay attention to the angle of positioning as shown in fig. 3.

4) Take out the P preloading pin.