CeramicSpeed SlipCoat –

When Only the Cleanest is Good Enough!

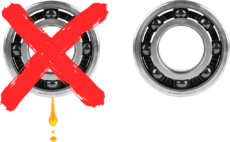

Can you make a bearing run without lubrication? So far, the answer from CeramicSpeed has been the same “All bearings can run without lubricant – but not for a very long time”.

How to provide a solution for applications where ANY tiny drop of oil could ruin products, processes, or sensitive environments?

So, when one of CeramicSpeeds good customers came up with the exact challenge of making a “lubrication free” bearing where no dripping or splatter of lubricant was acceptable and with a run time of more than 3.000 hours of operation, CeramicSpeed gave the challenge to their in-house specialists.

Solution tested:

Ball bearing size 6202:

– Stainless steel rings (AISI440C)

– Silicon Nitride rolling elements

– CeramicSpeed SlipCoat treatment

Limitations:

– As the coating remains soft it creates some friction in the bearing. Hence the solution is not recommendable where low friction / high speed is a key performance focus. CeramicSpeed SlipCoat is available in any ball bearing configuration with short lead time!

Technical Highlights:

– Coating material is FDA and EN/1935 compatible

– Functional in temperatures from -20ºC until 260ºC

– Extremely chemically inert

– Transparent / colorless

For more information do not hesitate to contact us.